By Stacey Dresner

WEST HARTFORD – In an effort to offer aid to first responders and medical personnel dealing with the COVID-19 crisis, several New England Jewish Academy (NEJA) students have been creating disposable face shields using clear binder covers, weather-stripping, and ribbon.

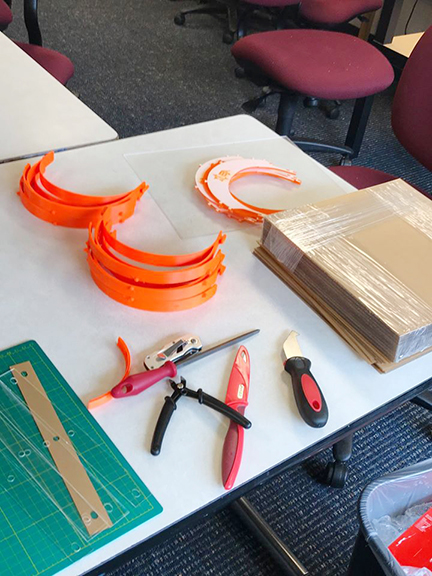

While the students were working hard at home on their face shields, Zach Towne, a NEJA upper school science teacher and head of the school’s Curtis Robinson Center (CRC) for Business and Innovation – which is described on the school’s website as “a space to explore entrepreneurship, creativity, innovation and non-linear thinking with state-of-the-art resources and tools” – worked to create reusable face shields using the CRC’s 3D printers and laser cutters.

“Originally, the school saw the global efforts to help and felt a strong need to support both the Jewish community and the community at large. Since opening the Curtis Robinson Center, the idea of tikkun olam has been a central tenet that we’ve been looking to develop, and this presented the right moment,” said Towne, a biology, AP biology and anatomy teacher at the Jewish high school, which is located in West Hartford, and serves the Jewish communities of West Hartford and New Haven in Connecticut and Springfield in Massachusetts.

“My specific motivations were to contribute to the pandemic in a thoughtful and intentional way. We certainly have a privilege in our access to the CRC and we wanted to leverage that to the benefit of everyone around us,” he told the Ledger.

Towne had learned that Prusa, a company in the Czech Republic, had designed templates for sturdy, reusable face shields using 3D printers and laser cutters. He was able to get the templates free from Prusa, which like many companies and universities, are sharing their plans for different products globally in the interest of serving the greater community, especially in this time of crisis.

“It’s all an open source,” Towne said. “It’s all free and everyone is pretty collaborative. That is sort of the spirit of the whole thing. It’s a way that everyone can contribute right now.”

Although NEJA has been closed since mid-March, Towne has had permission to access its Curtis Robinson Center, so after getting the template for the face shields from Prusa, he got to work.

“The laser cutter uses a laser to cut specific shapes out of materials, so we used a laser cutter to cut the shields out of a sheet of plexiglass,” he explained. “The plexiglass has to be relatively thin in order to bend to the contour of your face, and it has to be flexible and not just shatter when you try to put any pressure on to it.”

The 3D printer came into play when making the orange plastic headbands that sit on the forehead. The template for the headbands is sent from a computer to the 3D printer where plastic filament melts and then is shaped into the headband form.

An adjustable elastic band is also attached to the shield, which goes around the back of the head to make it tighter. Each face shield costs about $5 to make and is one-size-fits-all.

It wasn’t always smooth sailing. Town encountered a roadblock at the beginning of the project when he found that the supply of local plexiglass had been depleted. “Even the Home Depot was completely empty,” Towne noted.

He was finally managed to secure 100 sheets of the plexiglass from a company in California.

Getting the plastic filament was easier.

“The company that makes 3D printers has been pretty good about keeping the filament in stock,” he said. “We’ve gone through one two-pound roll, which is enough to make roughly 20 of those bands, so we just ordered four more, which should make about 100 bands.”

Towne says he made a few mistakes at first.

“I had to redesign the face shield to fit properly to the bands. It took me a while to get the measurement exactly right. So, I went through 15 of the plexiglass sheets because they kept cracking, and if they crack you can’t use them because that’s a surface for bacteria or virus to get through,” he said.

Towne was able to share his accomplishment with his NEJA students online.

“[During the quarantine] I have held a lot of my classes in the CRC and walked my students through the steps [for creating the shields],” he says. “While I decided to make the shields before showing the process to the kids, I thought it was important to highlight that we can all take action right now, even if we’re stuck at home…I especially remember showing the students the first mask where the pieces fit together because I thought I was going insane after a few failures.”

Towne says that NEJA students soon will be involved in the production process.

When he spoke with the Ledger late last week, Towne reported that he was getting ready to train a student to make the printed masks at the school, “so that we can increase output and get the students further involved,” he said.

Dr. Isaac “Yitz” Moss, co-president of NEJA, said told the Ledger that the school is currently looking into where they can donate the face shields. One recipient will be UConn Health in Farmington, where Moss is an assistant professor in the Department of Orthopedic Surgery, and where Towne himself will be entering medical school in September.

Moss said he is also hoping that they can donate some of the shields to other community organizations that might need them, like Hebrew Healthcare.

“The purpose of the Curtis Robinson Center for Business and Innovation is, first, [to serve] students, but we also realize that NEJA is a community organization and this is a very tangible way that we can give back to the community during this crisis,” Moss told the Ledger. “We are excited that we have the resources in our school and the ability to provide this service to the community.”

Main Photo: Some of the reusable face shields NEJA is donating to medical professionals dealing with the Covid-19 crisis.

Southern New England Jewish Ledger

Southern New England Jewish Ledger